Akwai dubban robobi a kasuwa don yin samfura cikin sauri ko ƙananan samarwa - zabar robobin da ya dace don wani aikin na iya zama mai ban sha'awa, musamman ga masu ƙirƙira ko masu son kasuwanci. Kowane abu yana wakiltar daidaitawa dangane da farashi, ƙarfi, sassauci da ƙarewar ƙasa. Wajibi ne a yi la'akari ba kawai aikace-aikacen sashi ko samfurin ba, har ma da yanayin da za a yi amfani da shi.

Gabaɗaya, robobin injiniyan injiniya sun haɓaka kayan aikin injiniya waɗanda ke ba da ƙarfi mafi ƙarfi kuma baya canzawa yayin aikin masana'anta. Hakanan ana iya canza wasu nau'ikan robobi don inganta ƙarfinsu, da tasiri da juriya na zafi. Bari mu nutse cikin kayan filastik daban-daban don yin la'akari dangane da aikin ɓangaren ko samfur na ƙarshe.

Ɗaya daga cikin resins na yau da kullum da ake amfani da su don yin sassa na inji shine nailan, wanda kuma aka sani da polyamide (PA). Lokacin da aka haɗe polyamide tare da molybdenum, yana da ƙasa mai santsi don sauƙin motsi. Duk da haka, ba a ba da shawarar gear nailan-on-nailan ba saboda, kamar robobi, sun saba manne tare. PA yana da babban lalacewa da juriya na abrasion, da kyawawan kaddarorin injina a babban yanayin zafi. Nailan abu ne mai kyau don buga 3D tare da filastik, amma yana sha ruwa akan lokaci.

Polyoxymethylene (POM) kuma kyakkyawan zaɓi ne don sassa na inji. POM resin acetal ne da ake amfani da shi don yin DuPont's Delrin, filastik mai mahimmanci da ake amfani da shi a cikin gears, sukurori, ƙafafun ƙafa da ƙari. POM yana da ƙarfin sassauƙa da ƙarfi, ƙarfi da tauri. Koyaya, POM yana lalata da alkali, chlorine da ruwan zafi, kuma yana da wahala a manne tare.

Idan aikin ku wani nau'in akwati ne, polypropylene (PP) shine mafi kyawun zaɓi. Ana amfani da polypropylene a cikin kwantena na abinci saboda yana da juriya da zafi, ba zai iya jurewa mai da sauran abubuwa ba, kuma baya sakin sinadarai, yana sa ya zama lafiya a ci. Har ila yau, Polypropylene yana da ma'auni mai kyau na ƙwanƙwasa da ƙarfin tasiri, yana sauƙaƙe yin madaukai waɗanda za a iya lankwasa akai-akai ba tare da karya ba. Hakanan za'a iya amfani dashi a cikin bututu da bututu.

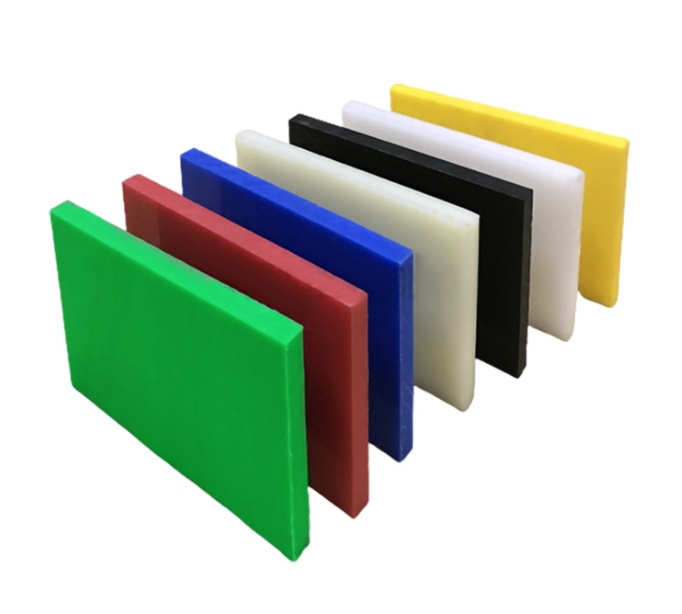

Wani zaɓi shine polyethylene (PE). PE shine filastik na yau da kullun a duniya tare da ƙarancin ƙarfi, tauri da taurin kai. Yawanci farin roba ne mai ruwan madara da ake amfani da shi don yin kwalaben magani, madara da kwantena. Polyethylene yana da matukar juriya ga nau'ikan sinadarai masu yawa amma yana da ƙarancin narkewa.

Acrylonitrile butadiene styrene (ABS) abu shine manufa don kowane aikin da ke buƙatar juriya mai ƙarfi da tsayin daka da juriya. ABS yana da nauyi kuma ana iya ƙarfafa shi da fiberglass. Yana da tsada fiye da styrene, amma yana daɗe saboda taurinsa da ƙarfinsa. Fusion-molded ABS 3D ƙirar ƙira don saurin samfuri.

Ganin kaddarorin sa, ABS zabi ne mai kyau don wearables. A Star Rapid, mun ƙirƙiri akwati na smartwatch don E3design ta amfani da allurar ƙera baƙar fata da aka riga aka yi wa fentin ABS/PC filastik. Wannan zaɓin kayan yana sa na'urar gabaɗaya ta yi haske sosai, yayin da kuma tana ba da wani akwati wanda zai iya jure girgiza lokaci-lokaci, kamar lokacin da agogon ya faɗo ƙasa mai wuya. Babban tasiri polystyrene (HIPS) zaɓi ne mai kyau idan kuna buƙatar abu mai juriya da tasiri. Wannan abu ya dace da yin amfani da kayan aiki mai dorewa da kayan aiki. Kodayake HIPS yana da araha, ba a la'akari da su a matsayin abokantaka na muhalli.

Yawancin ayyuka suna kira ga resins ɗin gyare-gyaren allura tare da elasticity kamar roba. Thermoplastic polyurethane (TPU) zaɓi ne mai kyau saboda yana da nau'ikan ƙira na musamman don babban elasticity, ƙarancin zafin jiki da karko. Hakanan ana amfani da TPU a cikin kayan aikin wutar lantarki, rollers, insulation na USB, da kayan wasanni. Saboda juriya mai ƙarfi, TPU yana da babban abrasion da ƙarfin ƙarfi kuma ana iya amfani dashi a cikin mahallin masana'antu da yawa. Duk da haka, an san shi don shayar da danshi daga yanayi, yana da wuya a aiwatar da shi yayin samarwa. Domin yin gyare-gyaren allura, akwai thermoplastic rubber (TPR), wanda ba shi da tsada kuma mai sauƙin iyawa, kamar yin rikon robar mai girgiza.

Idan sashinka yana buƙatar bayyanannun ruwan tabarau ko windows, acrylic (PMMA) shine mafi kyau. Saboda tsayin daka da juriyar abrasion, ana amfani da wannan kayan don yin tagogi masu lalacewa irin su plexiglass. PMMA kuma yana gogewa da kyau, yana da ƙarfi mai ƙarfi, kuma yana da tasiri don samar da ƙarar girma. Koyaya, ba shi da tasiri ko juriya na sinadarai kamar polycarbonate (PC).

Idan aikin ku yana buƙatar abu mai ƙarfi, PC ya fi PMMA ƙarfi kuma yana da kyawawan kaddarorin gani, yana mai da shi zaɓi mai dacewa don ruwan tabarau da tagogin harsashi. Hakanan ana iya lanƙwasa PC kuma a kafa shi a cikin zafin jiki ba tare da karye ba. Wannan yana da amfani don yin samfuri saboda baya buƙatar kayan aikin ƙira masu tsada don samarwa. PC ya fi acrylic tsada, kuma tsawaita bayyanarwa ga ruwan zafi na iya sakin sinadarai masu cutarwa, don haka baya cika ka'idojin amincin abinci. Saboda tasirinsa da juriya na karce, PC ya dace don aikace-aikace iri-iri. A Star Rapid, muna amfani da wannan kayan don yin gidaje don Muller Commercial Solutions tashoshi na hannu. An ƙera ɓangaren CNC daga wani shinge mai ƙarfi na PC; tun da yake yana buƙatar zama cikakke, an yi masa yashi da hannu kuma an goge shi da tururi.

Wannan taƙaitaccen bayani ne na wasu robobi da aka fi amfani da su wajen kera. Yawancin waɗannan za a iya gyaggyara su tare da filaye daban-daban na gilashin, UV stabilizers, lubricants ko wasu resins don cimma wasu ƙayyadaddun bayanai.

Gordon Stiles shine wanda ya kafa kuma shugaban Star Rapid, mai saurin samfuri, saurin kayan aiki da ƙananan masana'anta. Dangane da asalin aikin injiniyansa, Stiles ya kafa Star Rapid a cikin 2005 kuma a ƙarƙashin jagorancinsa kamfanin ya haɓaka zuwa ma'aikata 250. Tauraruwar da sauri suna aiki da ƙungiyar Injiniya da masu fasaha waɗanda ke haɗuwa da fasahar-Enduresawa kimanin 3D da kuma ka'idojin masana'antar gargajiya da ƙwararrun masana'antu. Kafin shiga Star Rapid, Styles mallakar kuma sarrafa STYLES RPD, babban kamfanin sarrafa kayan aiki da sauri na Burtaniya, wanda aka sayar wa ARRK Turai a cikin 2000.

Lokacin aikawa: Afrilu-19-2023